One frequently asked question in logistics is, “What are flexible intermediate bulk containers (FIBCs)?” Often FIBCs are referred to as bulk bags, super sacks, and totes. A flexible intermediate bulk container (FIBC) is a container that has been used to transport bulk materials for manufacturers in the agricultural, chemical, and construction industries since the 1950s. But what is a bulk container used for? Conceptually, it is simply a very big bag – a bag that is designed to transport and store over 2000 pounds of a flowable material.

Flexible Intermediate Bulk Containers Definition

Flexible Intermediate Bulk Containers Definition

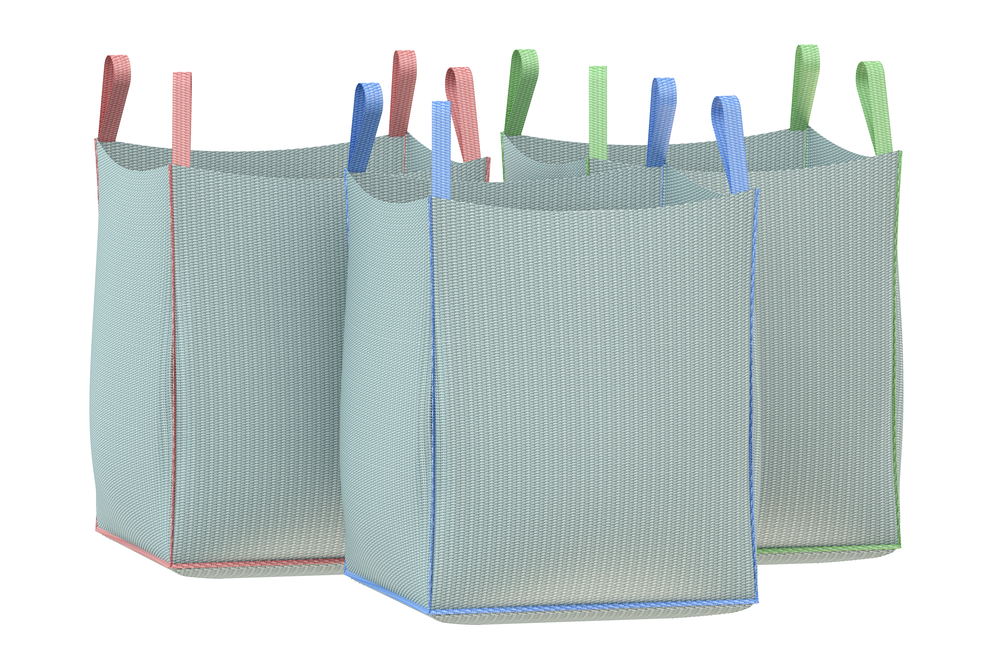

FIBCs are large, cubic, flexible containers made out of a woven fabric, usually with four loops on each of the top four corners. When filled with material, these industrial bulk bags can weigh up to 2000 pounds or more. The loops are designed to be placed around the forks of a forklift to move the container from one location to another. You can also place the bag on a pallet and lift it up from underneath – an option that places considerably less stress on the bag itself. However, pallets are not necessarily needed.

What is a flowable material?

Flowable material means anything that is dry and granulated. For example, imagine an hourglass. The sand in an hourglass flows from one side to the other through a tiny opening. This is a perfect example of what a flowable material is. Other examples include dirt, cement, powdered chemicals, and even food.

A Short History of Flexible Intermediate Bulk Containers

No one knows when FIBCs first came into widespread use. Their history has been traced to the 1950s, and they have been used for a variety of purposes. Initially, they were manufactured from PVC-coated nylon or polyester. With the advent of polypropylene in the 1960s, FIBCs started seeing widespread use throughout the chemical industries for storing powdered and granulated chemicals.

What Makes These Bags Popular?

The ratio of cost and benefit is one of the best that anyone can hope for. When the bag is empty, it weighs nothing more than five to seven pounds. When it is full, it will weigh as much as 2000 pounds and can transport a full metric ton of material. Although reusable, many people simply cut the bag open when they are ready to pour the transported material out. These bags are economical, inexpensive to own, and make managing loose, flowing materials simple and easy.

Maximize Your Space with a Smaller Footprint

When stacked side-by-side, your space is maximized with FIBCs. Since they are made out of a flexible material, you have a little bit of play in the container itself, enabling you to fit more material in a smaller footprint. When stacked in a semi-tractor trailer, two containers sitting side-by-side will fill the width of the truck perfectly.

Different Forms and Properties

So what types of FIBC bags are out there? These bags come in many different structural forms with various electrostatic properties. Structural forms refer to how the bag is made, its different features, and the specifications that comprise its structure. These can include construction types such as u-panel, circular, and baffle.

Common Uses

Just about any dry, granulated material can be securely stored and transported in an industrial bulk container. Primarily used by the chemical and agricultural industries, these bags can store and transport a variety of materials. Food products include seeds, cereal, starch, grains, beans, and peanuts. Other agricultural products that may be stored and transported in bulk bags are topsoil, fertilizers, gravel, and sand. Bulk bags are also used for chemicals and construction materials such as pigments, cement, fiberglass, plastics, detergents, and other powdered chemicals.

FIBCs are flexible, can often be disposable, and will get a job done efficiently and within budget. With FIBCs, users are given the ability to transport and store these materials at a much lower cost than any other possible option.

Thank you for reading our blog! How can we help you? Contact us today if you’re ready to place an order for our flexible intermediate bulk containers.

Sorry, the comment form is closed at this time.