Sometimes it is easier when you only have one variety to choose from but sometimes variety helps our businesses run more efficiently and can save us money. New innovations have allowed the packing industry to be more environmentally friendly and allow for each business to personalize their loads. Western Packaging offers three types of strapping to suit your needs and we’re going to help you to decide whether polypropylene, steel, or polyester is right for you.

Choosing the right strapping material can reduce product damage, improve shipping efficiency, and lower overall freight costs. According to industry data, load shifting and packaging failure account for a significant percentage of in-transit damage claims, making proper strapping a critical part of any packaging strategy.

Key Takeaways

- Polypropylene is cost-effective and ideal for light to medium loads

- Steel offers unmatched strength for extreme applications

- Polyester provides high tension retention and recyclability

- Choosing the right strapping improves safety, efficiency, and cost control

Why Do I need Strapping?

Strapping is an important part of storing and shipping goods. It adds extra protection and secures heavy items so your product stays the way you packed it. It also protects the merchandise and goods of others.

Strapping is also part of the shipping requirements for all major shipping companies like USPS or UPS. You can visit their website for specific requirements and specifications, typically pallets over 150 pounds require some sort of strapping. Adding the extra reinforcement saves you time and money when it’s all said and done.

The International Safe Transit Association (ISTA) reports that proper unitizing and strapping can reduce shipping damage by up to 30 percent, helping businesses avoid costly returns and replacements.

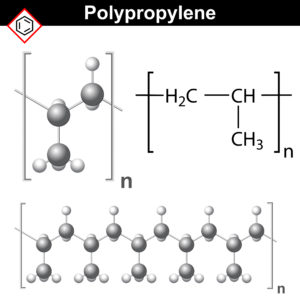

Polypropylene Strapping, The Economical Choice

Polypropylene is the newest technology in strapping materials, it has an abundance of benefits and is very versatile. Polypropylene is used in the food industry, for newspapers, corrugated boxes, and general packaging. It is very economical and is used for light, medium, and some heavy loads. This strapping is often chosen by businesses looking to balance cost and performance, especially for short-term storage or lighter palletized shipments.

Unlike Polyester and steel, polypropylene allows for more elongation but over time it may not be recoverable so if you have extra heavy loads this is not the strapping for you. This type of strap can be printed on and applied with manual tools, automatic machines, semi-automatic machines, hand, electric, or battery operated tools. A high-quality propylene strap is a great choice for those without hot, sharp, or extra heavy loads.

Steel, Standing The Test of Time

Steel was the strapping that paved the way for everything after it. It is the oldest and is still the strongest out of all the straps available. If you have heavy-duty loads and do not need any elongation steel may be a good choice for you. It is also used for sharp or heated loads that would melt or cut through other types of strapping. Steel strapping is commonly used in industries such as metal fabrication, lumber, and construction where maximum strength is required.

The downside to steel is that it is on the expensive side, it is rather dangerous with its sharp edges, and it’s hard to recycle. Steel strapping can be applied with manual tools or electric and battery operated tools. Many industries have started to phase out steel straps but if you feel this is the right choice for your business Western Packaging can help you.

Polyester Strapping, Strong and Recyclable

Polyester strapping is the strongest next to steel with a high level of retained retention making it a great choice for those with heavy-duty loads. Polyester is the most rigid, is nick resistant, and recyclable making it a practical choice for those looking for these characteristics. If your load needs high-tension initially along with retainable tension, polyester is the strap for your shipment. .Studies show that polyester strapping retains a much higher percentage of its initial tension over time. Up to about 70% compared to polypropylene, which can lose nearly half its applied tension within an hour. This superior tension retention makes polyester an ideal choice for shipments that may settle, shift, or experience long transit times

The downside to polyester strapping is that there is not a lot of elongation to the straps. So if you need something with a little “give” this strap will not give you that, a high-quality polypropylene is the better option. You can apply and secure your polyester straps with manual tools, electric or battery operated tools, or automatic machines.

Additional Points to Consider When Choosing Strapping

When selecting strapping, consider storage conditions, load movement, and environmental exposure. Loads that expand or contract benefit from straps with elongation, while static, heavy loads require high retained tension. Temperature, moisture, and handling frequency should also influence your decision.

According to the World Steel Association, steel has a recycling rate of over 70% globally, while polyester and polypropylene are both recyclable plastics when handled through proper recycling programs. Choosing recyclable strapping can help businesses reduce waste and meet sustainability goals.

Learn More from Western Packaging

To explore your options further, check out:

- Our strapping product page here

- Using Polypropylene Straps in the Agricultural Industry

Call Today For Questions and Orders

If you have specific questions about polypropylene, steel or polyester strapping give Western Packaging a call. We have people who are knowledgeable and ready to answer any questions you may have. We look forward to hearing from you!

Sorry, the comment form is closed at this time.