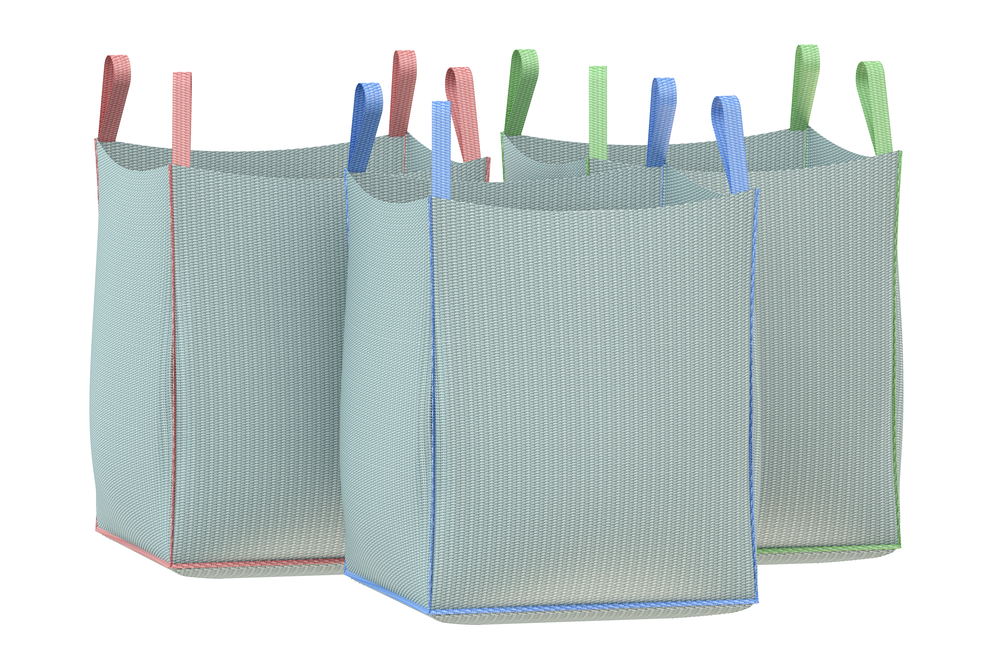

UN certified FIBC bulk bags are designed and constructed to meet strict compliance regulations set by the United Nations. For the transportation and storage of hazardous materials, the UN requires these bags to undergo special testing, as well as manufacturing, before they can be certified. Companies that supply these bags must also be certified. Western Packaging is an agricultural packaging supply company that is certified to supply UN-certified FIBC bags.

Key Takeaways:

- Safety and Compliance: UN-certified FIBC bags must pass rigorous tests to ensure they are safe for transporting hazardous materials.

- Durability: These bags are made to be more durable than regular FIBC bags, increasing safety and reducing risks.

- Industry Use: Predominantly used in industries handling hazardous materials, ensuring safety and compliance with regulations.

Rigorous Testing for Certification

To be certified for storing and transporting dangerous materials, these bulk bags must prove their capability. Before receiving UN certification, they undergo a series of rigorous tests, including a top lift and a tear test, which ensure they can withstand extreme conditions.

In the top lift test, the bags are loaded with six times their maximum load in order to ensure they qualify for the 6:1 safety factor. These bags must also pass a tear test in which a 100mm (about 4 inches) is made on one of the sides of the bag before it is filled with its maximum load capacity. The bag is then filled to twice its load capacity. And, finally, it is suspended for five minutes with its maximum safe workload.

Enhanced Safety Features

The design of UN-certified FIBC bags includes enhanced safety features to handle the demands of transporting and storing hazardous materials. The increased thickness and strength of the materials used in UN-certified bags provide better resistance to punctures and tears, essential for preventing leaks and contamination.

These bags also feature specialized liners and coatings that can be tailored to protect against specific hazards, such as moisture, chemicals, and UV radiation, ensuring the integrity of the contents and safety of the handlers.

Certification Process Explained

Obtaining UN certification for FIBC bags involves a detailed and stringent process. This includes an assessment of the quality management systems of the manufacturing facility, detailed documentation of the manufacturing process, and periodic audits to ensure ongoing compliance. Each UN-certified bag carries a unique identification code that traces back to its batch, providing assurance of its quality and compliance.

Regular Versus UN Approved

The design of UN-certified FIBC bags includes enhanced safety features to handle the demands of transporting and storing hazardous materials. The increased thickness and strength of the materials used in UN-certified bags provide better resistance to punctures and tears, essential for preventing leaks and contamination.

The industry standard safety ratio of standard bulk bags is 5:1. UN approved bags, however, must achieve a safety ratio of 6:1. The UN certified bags must also undergo immense testing that proves their ability to handle the workload and other possible scenarios that could arise in the process of storing or transporting materials.

Uses And Benefits

UN certified FIBC bags are used across many different industries, however, they specialize in those that deal with the handling of hazardous materials. These bulk bags are certified to prevent any possible damage or destruction of property or product, as well as the environment. They are also designed to protect people involved in these industries, which often deal with toxic and radioactive waste, corrosives, flammables, and explosives.

The versatility of these bags makes them indispensable in sectors such as mining, chemical manufacturing, and waste management. Their robust construction not only enhances safety but also improves operational efficiency by allowing safe and secure handling of materials.

The benefits of using these specialized bags are numerous, including improved safety for workers, environmental protection, and enhanced efficiency in operations. Their ability to be customized with various liners and treatments also makes them highly adaptable to specific industry needs.

Contact Us For Your FIBC Needs

Are you looking to purchase UN certified FIBC bags? Western Packaging has completed all training requirements and has received the required certification for the sale and supply of these bags. We also provide EBS Handjet printers, hay sleeves, and Wulftec products, as well as more. Contact us today and learn more about our products and how we can help your business. We look forward to hearing from you soon.

Sorry, the comment form is closed at this time.