Bulk bags are a staple of the shipping industry and can be used to store and transport a wide range of goods. No matter the material you need to store or move around, bulk bag containers provide a versatile and secure way of storage. Our team here at Western Packaging recommends bulk bag products when you need to store a large number of products.

What Are Bulk Bags?

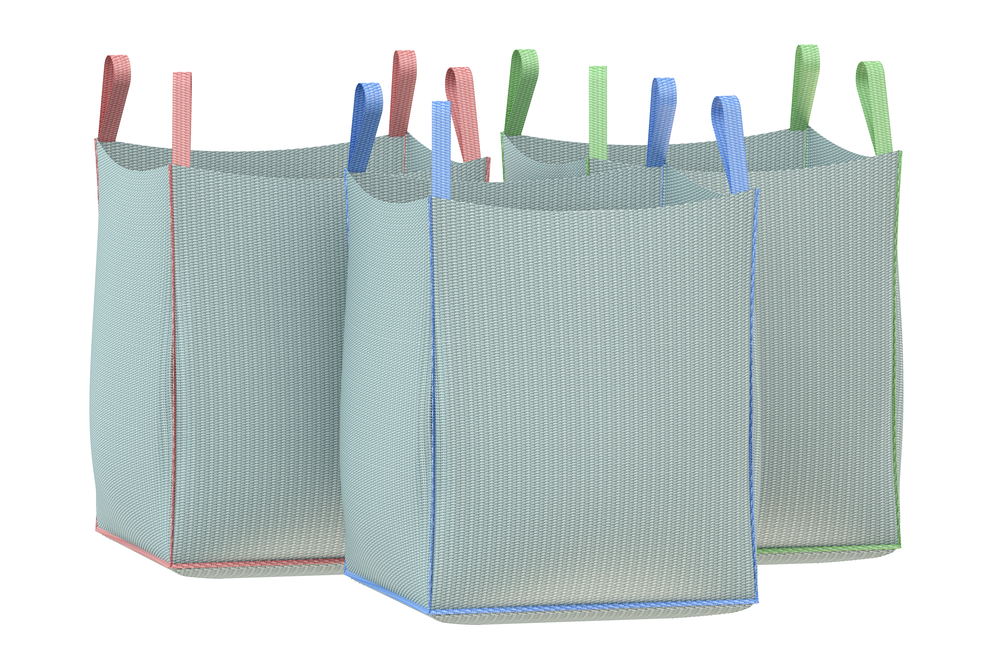

A bulk bag is a heavy-duty material handling bag or industrial container that is designed to transport free-flowing goods. These bags are designed with safe transport in mind. Bulk bags allow you to transport small materials by conducting varying levels of static.

The reason why these bags are popular in the transport business is because of their flexibility, strength, and efficient loading and transportation. If your company regularly loads a large amount of materials, such as sand, grain, or chemical materials, bulk bags are a great choice. These bags will make your life much easier. Here are some of the things bulk bag products can be used for:

The Food Industry

If you’re transporting materials that are flakey, granular, or powdery, bulk bags can come in handy. The United States often produces a billion bushels of winter, spring, and drum wheat each season. The majority of these are shipped across the country or exported to other countries.

Bulk bags’ flexibility and strength are big reasons why bulk bags are popular in the food industry. Other goods frequently transported by the food industry include sugar, seeds, nuts, potatoes, and flour. Most bulk bags used for shipping are also compliant with food safety standards set by the AIB, BRC, and the Global Food Safety Initiative.

The Construction Industry

The versatility bulk bags provide makes bulk bags the optimal shipping solution in the construction industry. When you’re shipping goods in the construction industry, the goods are usually heavy and irregularly shaped. Bulk bags are strong and versatile and can store a wide range of materials.

Potential uses of small or large bulk bags in the construction industry include shipping gravel, cement, resin, pallets, minerals, slag, and clay. The reason why bulk bags are popular in the construction industry is because bulk bags can withstand between 2,000 and 3,000 pounds each. If you’re looking to ship heavy or irregularly shaped products, bulk bag products may be the best choice for you.

The Chemical Industry

Bulk bags are designed to withstand electric charges and hazardous materials, making them an optimal choice for shipping chemical industry goods. Different degrees of static charge can be handled and dissipated using Type A, B, C, and D bulk bags. Specifically, Type C and D bags work most effectively for this usage. In Type D, sparks and discharges are prevented without grounding, as the fabric is anti-static and static dissipative.

In Type C, non-conductive polypropylene textiles are woven in a grid pattern with a grounding point. Other shipping options in the chemical industry, such as Gaylord boxes, don’t provide the flexibility that anti-static bulk bags do. Bulk bags can also act as hazardous waste removal bags.

FIBC Types And Manufacturing

Static electricity might build up when finely ground materials are poured into or released from FIBCs (or bulk bags). When packing flammable and combustible substances or in an area where combustible dust exists, it is crucial to prevent or remove the build-up of electrical charges. FIBCs come in four different types, each with distinctive features to ensure safe use. Here is some more information about the various FIBC fabric types and how to most effectively utilize them.

Type A Bulk Bags

Polypropylene with a standard weave and other non-conductive materials are used to make Type A FIBCs. As products or materials are filling or being removed from these bags, they may brush against or pass over the interior surface of the bulk bag, generating static electricity. Type A FIBCs do not offer any static protection if or when this occurs.

The area surrounding a Type A FIBC should be kept free from any flammable gasses or liquids. Type A bulk bag packaging should not be used for or in scenarios when:

- When there is a flammable atmosphere present with a minimum ignition energy of ≤1,000mJ.

- When the FIBC is in an area that has flammable solvents or gases present.

- Storing or transporting any flammable product or materials.

Non-flammable materials and products can be transported safely by utilizing type A bulk bags.

Type B Bulk Bags

Because they are composed of non-conductive materials such as plain-woven polypropylene textiles, Type B FIBCs are similar to Type A bulk bags. Like Type A bulk bags, Type B bags cannot dissipate static electricity and its build-up. To prevent a situation where highly energetic and dangerous propagating brush discharges develop, Type B FIBCs are constructed from materials with a low breakdown voltage, unlike Type A’s. Type B bulk bags are safe for use when:

- The immediate environment contains dust with ignition energies that are less than 3mJ.

- There are no flammable solvents or gases in the immediate vicinity of the bag.

- For safely transporting dry, flammable powders.

Despite its ability to stop brush discharges from spreading, Type B bulk bag containers are not regarded as anti-static bulk bags as they remain unable to eliminate electrostatic charges. For this reason, it is not recommended to utilize these bags in any circumstance or area where there may be flammable gases or solvents.

Type C Bulk Bags

Type C bulk bags are constructed from non-conductive polypropylene textiles interlaced with conducting threads that are often sewed in a grid pattern. They are also referred to as conductive FIBCs, anti-static bulk bags, or ground-able FIBCs. During filling and emptying, these conducting threads have to be linked to a specified earth/ground and be electrically interconnected. Type C bulk bags should not be used in instances when:

- There is resistance between a groundable point and any FIBC location.

- Whenever ground connection has been damaged or is completely nonexistent.

The safe usage of Type C bulk bags needs to have this connection to the earth/ground while filling and emptying. When this is present, these bags can safely be used to transport flammable powders and in areas where flammable gases, vapors, and dust exist.

Type D Bulk Bags

To safely avoid incendiary sparks, brush discharges, and propagating brush discharges, Type D FIBCs are constructed from antistatic and static dissipative fabrics. The fabric used to make Type D anti-static bulk bags has quasi-conductive threads in it, which safely release static electricity into the atmosphere through a low-energy corona discharge. This means that there is no need to link the FIBC to a designated ground/earth.

Type D FIBCs can safely and securely be used for:

- Packaging and handling flammable products or materials, such as flammable powders.

- Ideal for use in flammable and combustible environments where dusts, gases, and vapors may be present.

When conductive elements, such as grease or other flammable or combustible compounds, are present on the surface of the FIBC, they are not recommended to be used.

Western Package Offers Bulk Bags

Our team here at Western Packaging offers bulk bag containers to help you ship heavy and irregularly shaped goods. Bulk bags come in a wide range of sizes but can also be custom-made to fit a specific filling machine. Our bags used for shipping are made with liners designed to prevent moisture from forming in the bags.

Our single-trip, large bulk bags are made with a 5:1 safety ratio and can withhold a working load between 500-4,000 pounds. Multi-trips are made with a 6:1 ratio and can withhold a working load up to 5,000 pounds. Here at Western Packaging, our number one goal is to make sure your shipping needs are always met.

Sorry, the comment form is closed at this time.