If you operate any business, chances are you find yourself busy during certain times of the year. Business owners often look for products and ways to simplify their daily operations. If your business manufactures or ships products, a BOPP bag may be the perfect product for you to consider. But what are BOPP bags?

Never Heard of a BOPP Bag?

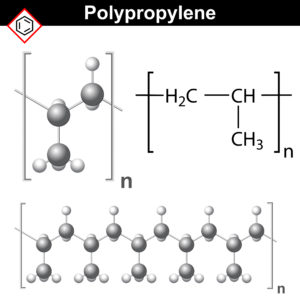

BOPP stands for Biaxially Oriented Polypropylene and is a specific packaging material. It is one of the most popular packaging materials because it’s durable. A BOPP bag is a sack that is woven and laminated using organic materials during the manufacturing process. These bags are extremely durable because they’re made with high-quality packaging materials.

The multiple layers of these bags allow the shipping of heavy materials. Multiple layers don’t pose an issue since they’re thin but highly durable. Companies can use these types of bags to package and ship any product. These bags are usually easy to design and advertise business brands. There are also many different types of BOPP bags. From a normal BOPP bag to BOPP cement bags, bopp laminated bags to windowed and lined BOPP plastic bags, there are BOPP bags for all packaging needs.

Manufacturing Process

Manufacturers make these bags using a reverse printing process. Multi-colored films are inserted into cylinders. Then the bag gets laminated with fabrics that are woven, cut, and stitched according to the customer’s specifications.

As a BOPP bag manufacturer, we take pride in delivering options for your packaging needs. Customers can choose multiple colors to create a unique style for their bags. The bags print in a machine called an engraved cylinder. This process does the brand and graphic design on the bags.

How Are They Different From Woven Bags?

Plainly, woven bags do not print out as well as BOPP bags. Their material is not as durable, so they do not hold up as well in the printing and laminating process. They also:

- Hold up against scratches and rips

- Are resistant to water

- Come with convenient handles

- Suitable for hot or cold products

- Easily transported

- Are recyclable

BOPP material is stronger and longer-lasting. The water-resistant properties of polypropylene provide a barrier to water, grease, oils, and other liquids. This saves the products and keeps customers satisfied. After the laminating process, the bag gives a glossy appearance that attracts consumers.

What Are The Benefits of BOPP Bags?

The great thing about these bags is that they are custom-made. Businesses can choose to place their brand on the bag and increase their marketing range. The high-quality material also allows companies to enhance their revenue through attractive branding and designs.

Using Them In Your Business

So what types of businesses can benefit from these BOPP bags? There are many ways to use these bags in any business. Food and beverage industries use these bags often. Businesses can use these bags for things such as:

- Pet and animal feed

- Fertilizers and pesticides

- Chemicals and resins

- Construction materials

- Any food packaging products of various weight

- Grasses and seed

- And more…

These bags combine the material of a regular plastic bag with another high-quality material. This process creates a unique combination of an unusual product. Don’t worry about the bag getting dirty. The high-shine finish allows you to easily wipe off the bag without washing it.

Stand Out To Customers

Products made with high-quality materials attract customers to purchase them. These materials make it easier to include plenty of colors and eye-catching graphics. The manufacturing process is also very cost-effective, another benefit for your customers and your business. If your products have attractive packaging, customers are more likely to purchase your products.

BOPP Bags Enhance Your Business

These bags are convenient and versatile for your business in so many ways. You can enhance your business advertising using any unique branding. We can customize any size and add it to your business specification. We import a variety of bags. Contact Western Packaging and increase your revenue today with our packaging products.